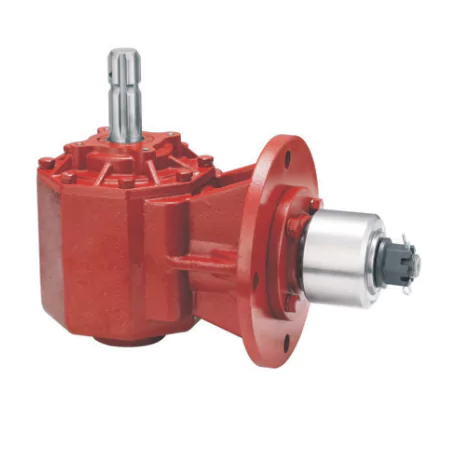

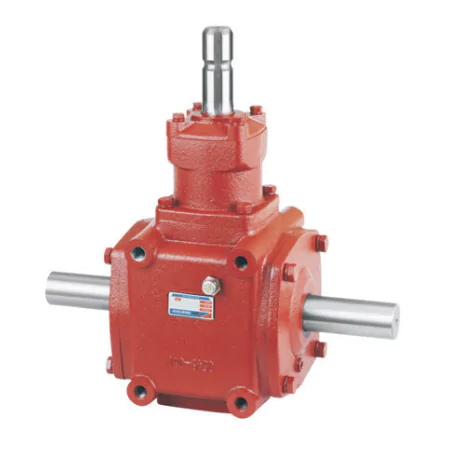

ROTARY CUTTER

GEARBOX

ROTARY CUTTER

GEARBOX

MODEL LIST

Rotary Cutter Gearboxes are key components in agricultural implements, transferring power from the tractor’s PTO or engine to cutting blades while ensuring stable performance. The internal gear set adjusts speed and torque for varying field conditions, and the robust design ensures long-term durability.

JENA offers a wide range of gearboxes for rotary cutters, mowers, and flail machines (30–300 HP). With 25+ years of OEM/ODM experience, JENA delivers reliable solutions to agricultural machinery manufacturers worldwide.

To view the detailed specifications of a model, please scroll down to the CATALOG DOWNLOAD section.

ORDER INFORMATION

MOQ | Delivery Time | Port of Loading | Get samples | Warranty | Customization | Delivery Term |

|---|---|---|---|---|---|---|

2 pieces | 30-60 days | Ningbo / Shanghai | Yes, it's ok. | 1 year | Available, contact with drawings | EXW · FOB · CFR · CIF · Others |

CATALOG DOWNLOAD

FAQ FOR BUYERS

Factory or trading company?

Jiaxing JENA Gearbox Co., Ltd. is a professional gearbox manufacturer with our own production facilities. We focus on precision engineering and strict quality control to ensure reliable and long-lasting performance.

What is your MOQ?

The minimum order quantity (MOQ) is typically 2 pieces. For non-standard or customized products, please send us the detailed specifications for a quotation.

Can I get a sample?

Yes, we can provide samples. For details, please contact our sales team.

What are your payment terms?

Our standard payment terms are 30% deposit and 70% before shipment by T/T, or 100% payment before shipment by T/T for new customers.

For long-term clients, we can explore more flexible solutions together.

Can you produce custom products?

Yes, customization service is one of our core services. Just tell us your requirements or send the drawings to us, and we’ll take care of the rest.

How to choose the right gearbox?

Check whether the photos and gearbox type (helical, bevel, worm, planetary, etc.) match.

Verify that the part/OE number or standard reference corresponds to your requirement.

Confirm the target machine or vehicle model, its duty cycle, and use year.

Finally, check the gearbox’s ratio, input/output shaft diameters, mounting dimensions, and allowable backlash to ensure accurate fit.

Do you offer branded customized packaging?

Yes, we can provide branded packaging.

We offer various custom packaging options for gearboxes, including reinforced cartons, wooden cases, palletized packaging, and individual protective boxes. Customized nameplates, labels, and other tailored packaging solutions are also available upon request.

What is your lead time?

For our existing models, the delivery cycle is usually 30-60 days;

For newly developed or customized products, the delivery cycle may be longer. Please consult our sales team for specific details.

How long is your product warranty?

All products manufactured by JENA are covered with a 1 Year warranty.

How to protect our rights?

All shipments are properly documented, and we provide OEM services under strict confidentiality. All related materials—such as drawings, manuals, and test reports—remain the sole property of the brand owner.

DIDN'T FIND WHAT YOU WERE LOOKING FOR?

JENA GROUP has been offering oem and odm service to customers around 25 years. All kind of ratios and applicaitons can be customized as customers needs.

ROTARY CUTTER GEARBOX OVERVIEW

Functions

- Power transmission & speed conversion — Converts tractor PTO speed (commonly 540 / 1000 RPM) into lower output speed and higher torque suitable for rotary blades, keeping cutting power stable under varying loads.

Durability & protection — Robust housings (cast iron / alloy steel) with corrosion-resistant finishes and effective sealing to keep dirt and moisture out, protecting gears and bearings.

Safety / overload protection — Slip clutches or shear-bolt devices (and in some designs torque-limiting clutches) interrupt torque transmission if the blades jam, preventing gearbox damage.

Typical Agricultural Applications

- Grass cutting & residue shredding — Drive rotary blades for mowing or chopping crop residues; blade speed (via gearbox ratio) affects crush size (coarse → field return; fine → feed).

Brush and woody-stem clearing — High-torque boxes handle heavier loads when cutting shrubs, brambles or small saplings.

Stubble management & field prep — Used with cutting or flail attachments to clear stubble before tillage or planting.

Orchard / vine alley work — Low-profile or compact designs enable cutting in narrow rows and constrained spaces.

Key Design Features

- PTO interface & spline standards — Matches tractor PTO types and splines; correct input sizing is essential for safe connection.

Ratio options & modular output — Multiple reduction ratios and adaptable output shafts to suit different blade types (Y-knives, hammers, etc.).

Floating / suspension features — Floating decks or suspension on some cutters let the gearbox/assembly follow ground contours and reduce impact loads.

Serviceability — External oil-fill/level/drain access, breathers and inspection features to simplify field maintenance.

Short Maintenance & Inspection Checklist

- Check oil level and condition regularly; many gearboxes use hypoid/gear oil (e.g., 80W-90) and require level checks every ~50 hours or per manufacturer instructions.

Inspect seals, shaft keys and blade mounting bolts before each season.

Replace shear bolts or reset slip clutches after overload events; record occurrences to diagnose recurring issues.

Verify compatibility: PTO speed/type, shaft diameters, keyway specs, mounting hole pattern and required ratio before ordering.

ABOUT JENA GROUP

Zhejiang JENA Transmission Technology Co., Ltd. was established in 2000, located in Jiaxing city, Zhejiang Province, east of China.

Our products include bevel gearboxes, parallel reducers, worm gear cases, and transmission housings — nearly a thousand types in total. These gearboxes are widely used in agricultural and industrial equipment such as rotary cutters, rotary tillers, flail mowers, fertilizer spreaders, post hole diggers, lawn mowers, hydraulic drive systems, and potato harvesters.

OEM gearbox solutions are also available to meet customized application needs. Contact our technical team to discuss your specific requirements.

Annual quantity over

Established in

Factory Employee

Export Destinations

REQUEST A QUOTE

OR GET MORE

INFORMATION

Leave us a message. We will contact within 12 hours.