BLOG

BLOG

Common Failure Points in Fertilizer Spreader Gearboxes and How to Avoid Them

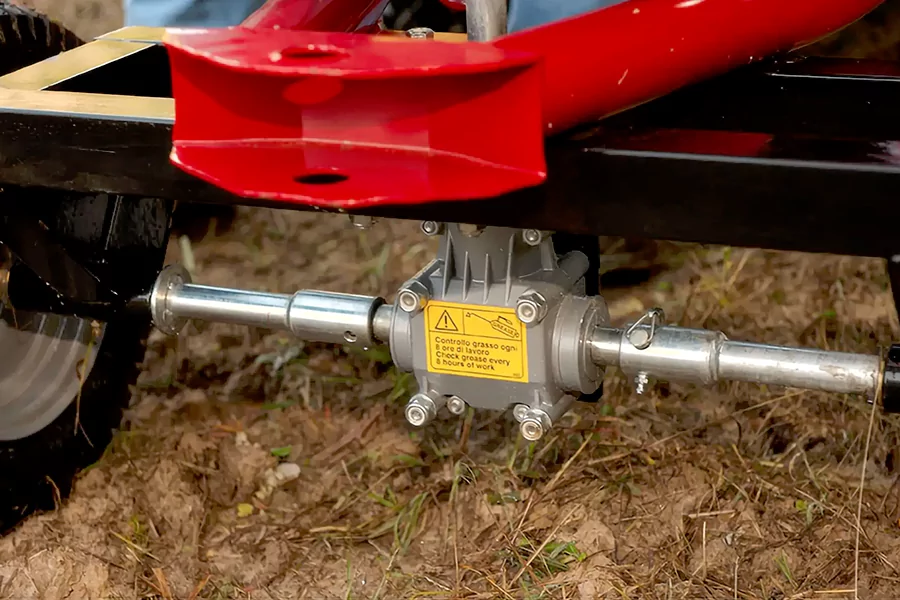

Fertilizer spreader gearboxes are critical components that convert tractor PTO power into rotational force to drive the spreading mechanism. These gearboxes work under harsh agricultural conditions—exposed to corrosive fertilizer dust, moisture, and heavy loads—so preventing failure is essential. Fertilizer is especially corrosive, and even short-term exposure can lead to rapid rust and component deterioration. Understanding the common causes of failure and following preventive measures can significantly extend the life of a fertilizer spreader gearbox.

Common Failure Points

1. Corrosion and Wear

Fertilizers, especially those containing nitrates and chlorides, are highly corrosive to metal surfaces. Residue left on or inside the gearbox causes oxidation, leading to rust, pitting, and thinning of gear teeth and housings. Over time, this degrades gear performance and structural integrity.

2. Lubrication Failure

Gearboxes rely on a continuous film of clean lubricant to reduce friction and dissipate heat. Lack of lubrication—or using degraded lubricant—leads to overheating, excessive gear wear, and micro-pitting. As the lubricant fails to protect the gear surfaces, friction increases and ultimately results in gear failure.

3. Overloading

Operating the PTO when the spreader is blocked or jammed introduces sudden torque spikes. Without a properly functioning slip clutch, this overload can cause catastrophic damage to the gearbox and tractor driveline. Gearboxes are designed to operate within a defined torque range, and exceeding it dramatically increases the risk of failure.

4. Contamination

Dust, dirt, and metal shavings inside the gearbox act as abrasives. Even microscopic particles can score gear surfaces, accelerate fatigue, and damage bearings. Contaminated lubricant becomes gritty and ineffective, increasing wear and heat generation.

5. Slip-Clutch Issues (Sticking/Binding)

Slip clutches are designed to protect the gearbox from sudden load shocks. If they seize up or are incorrectly adjusted, they fail to disengage under stress. This prevents the necessary “slip” action during blockages or transitions, transferring harmful forces directly to the gearbox and leading to binding, jamming, or internal breakage.

How to Avoid Fertilizer Spreader Gearbox Failures

1. Clean Thoroughly After Use

After each operation, wash down the hopper, gearbox housing, and spreading components to remove all fertilizer residue. Pay attention to hidden corners where powdery fertilizer may accumulate and cake. Let components dry fully, and apply a protective coating (such as light oil) on exposed metal to prevent rust.

2. Lubricate Regularly

Follow the manufacturer’s recommended lubrication schedule—typically every 20 to 50 hours of operation. Use high-quality gear oil or grease suitable for the gearbox’s environment. Periodically check oil levels and look for contamination. During seasonal storage, apply a thin protective layer to internal parts to reduce corrosion risk.

3. Maintain the Slip Clutch

Ensure the PTO slip clutch is correctly calibrated and functioning. Test it at least once per season to confirm it slips under overload. Clean or replace worn clutch discs, and never bypass this safety feature. A working slip clutch is your best defense against drivetrain shock and gearbox damage.

4. Operate Within Manufacturer Limits

Never engage the PTO with a blocked spreader or overfilled hopper. Avoid using clumpy, damp material that can cause jamming. Always clear blockages manually before powering up. Start PTO engagement slowly to reduce torque surges, and adhere to the specified load and speed limits for your gearbox model.

5. Perform Routine Inspections

Before each use, perform a visual inspection. Check for oil leaks, damaged seals, worn gear teeth, and unusual noise during operation. Ensure that mechanical linkages, including feed gates and headland engagement systems, move freely. Early detection of wear can prevent expensive failures later.

6. Keep the Hopper and Shutters Clean

Residual fertilizer or debris inside the hopper and shutters can retain moisture and promote corrosion. Make it a habit to empty and clean these areas after every application. A dry and clean system is less prone to buildup, blockage, and mechanical stress.

Why Choose JENA Gearboxes

JENA designs and manufactures robust fertilizer spreader gearboxes tailored for high-performance agricultural applications. Our gearboxes are built with corrosion-resistant housings, high-strength alloy gears, and sealed lubrication systems engineered to handle aggressive environments. Many JENA models include integrated slip clutches and user-friendly maintenance features to protect against overloads and extend service intervals.

With a proven track record of reliability and engineering excellence, JENA gearboxes help B2B buyers—from OEMs to farm equipment distributors—reduce downtime, increase productivity, and maximize equipment life in fertilizer spreading operations.

JIAXING JENA GEARBOX CO., LTD.

01

Jiaxing JENA Gearbox Co., Ltd. was established in 2000 and is located in Jiaxing, East China. With 100+ factory employees, JENA is dedicated to the R&D, manufacturing, sales, and service of agricultural gearboxes. Over the past decades, JENA has grown into a reliable supplier in the global agricultural gearbox industry, exporting to 60+ destinations worldwide.

02

Our product range covers bevel gearboxes, rotary cutter gearboxes, parallel reducers, worm gear cases, and custom transmission assemblies—covering nearly one thousand specifications. These products are widely used in grain harvesting equipment, forage machinery (mowers, balers, rakes, etc.), plant protection machinery, landscaping machinery, and oil extraction equipment. With an annual production quantity exceeding 300,000 units, JENA consistently delivers reliable performance and long-term durability for global OEMs and distributors.

Annual quantity over

Established in

Factory Employee

Export Destinations

REQUEST A QUOTE

OR GET MORE

INFORMATION

Leave us a message. We will contact within 12 hours.