BLOG

BLOG

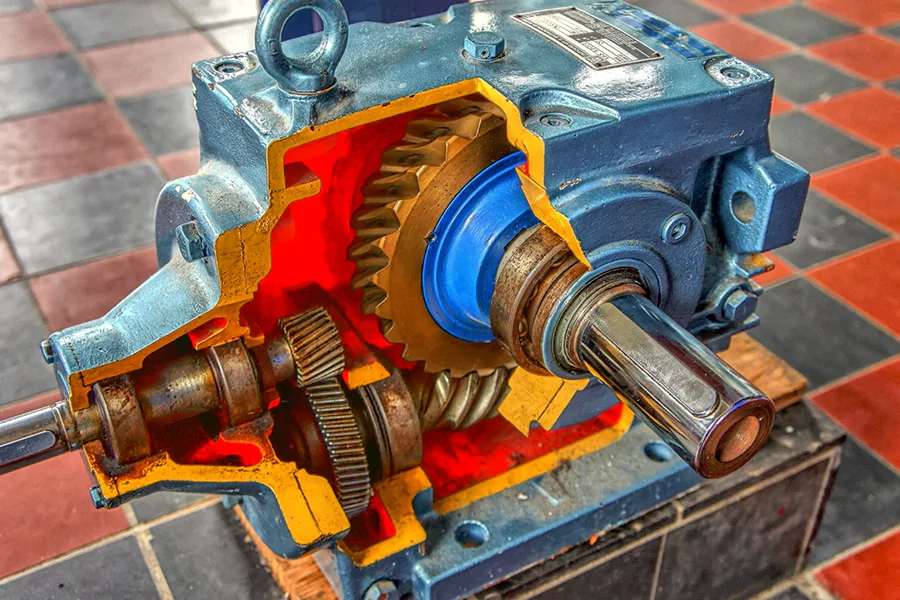

Common Rotary Cutter Gearbox Failures — and How to Prevent Them

A rotary cutter gearbox operates under constant shock, vibration, and heavy vegetation loads. Although the design is simple, failures such as overheating, oil leaks, and internal component wear are common if maintenance is overlooked. Understanding how these failures occur — and how to prevent them — is essential for ensuring long service life and reducing costly downtime.

Common Failures and Their Prevention

1. Overheating

How it happens:

Overheating is typically caused by low oil levels, degraded or incorrect oil, poor ventilation, or continuous heavy loads beyond the gearbox’s rating.

Prevention & solution:

- Check oil level before each use: Ensure the oil reaches the correct height, usually near the bottom of the side plug opening.

- Change oil regularly: Most manufacturers recommend changing oil every 200–500 operating hours or annually.

- Use the correct lubricant: Stick to the specified type and viscosity of gear oil to maintain proper lubrication.

- Improve ventilation: Clean grass and debris from the housing to allow proper heat dissipation.

- Reduce load: If the rotary cutter gearbox runs unusually hot, reduce cutting speed or lighten the vegetation load.

2. Oil Leaks

How it happens:

Leaks commonly originate from worn shaft seals, damaged gaskets, or loose filler and drain plugs.

Prevention & solution:

Inspect for leaks often: Check the housing surface and plug areas for any oil traces.

Replace seals or gaskets: Any sign of oil seepage around the input or output shaft should be corrected immediately.

Secure the plugs: Use proper thread sealant on fill and drain plugs to ensure a tight seal and prevent seepage.

3. Component Wear or Failure

How it happens:

Metal shavings in the oil indicate internal wear caused by lack of lubrication, contaminated oil, or impact damage. Hitting rocks, stumps, or hidden objects can also lead to sudden failure.

Prevention & solution:

Inspect oil during changes: If the oil contains metal particles, internal damage may already be underway.

Replace contaminated oil: Milky or dirty oil should be drained immediately to prevent accelerated wear.

Use proper torque: Ensure the blade carrier and mounting bolts are tightened to the recommended torque to reduce unnecessary stress.

Avoid foreign objects: Maintaining a clear cutting path reduces impact loads that can damage gears and bearings.

General Maintenance Tips

Listen for unusual noises: Grinding, clicking, or knocking sounds are early signs of gear or bearing failure. Stop operation immediately.

Check PTO connection: Ensure the PTO shaft is properly aligned and securely attached to the tractor’s PTO output.

Keep the gearbox clean: Remove accumulated debris with a brush or pressure washer to maintain cooling efficiency.

Protect the unit: If stored outdoors, use a waterproof cover and make sure the gearbox is completely dry to prevent rust and corrosion.

Why Proper Care Matters

A well-maintained rotary cutter gearbox delivers consistent torque, handles shock loads more effectively, and extends the overall service life of the implement. Neglecting lubrication, cooling, or inspection can lead to costly repairs — or complete gearbox replacement.

About JENA

JENA designs and manufactures rotary cutter gearboxes engineered for durability, ease of maintenance, and consistent field performance. Our gearboxes feature robust sealing, precise machining, and optimized ventilation to reduce heat and wear. Whether you need standard units or customized solutions, JENA’s engineering and support team can help you select the right gearbox and provide guidance on proper maintenance to keep your equipment performing at its best.

JIAXING JENA GEARBOX CO., LTD.

01

Jiaxing JENA Gearbox Co., Ltd. was established in 2000 and is located in Jiaxing, East China. With 100+ factory employees, JENA is dedicated to the R&D, manufacturing, sales, and service of agricultural gearboxes. Over the past decades, JENA has grown into a reliable supplier in the global agricultural gearbox industry, exporting to 60+ destinations worldwide.

02

Our product range covers bevel gearboxes, rotary cutter gearboxes, parallel reducers, worm gear cases, and custom transmission assemblies—covering nearly one thousand specifications. These products are widely used in grain harvesting equipment, forage machinery (mowers, balers, rakes, etc.), plant protection machinery, landscaping machinery, and oil extraction equipment. With an annual production quantity exceeding 300,000 units, JENA consistently delivers reliable performance and long-term durability for global OEMs and distributors.

Annual quantity over

Established in

Factory Employee

Export Destinations

REQUEST A QUOTE

OR GET MORE

INFORMATION

Leave us a message. We will contact within 12 hours.