BLOG

BLOG

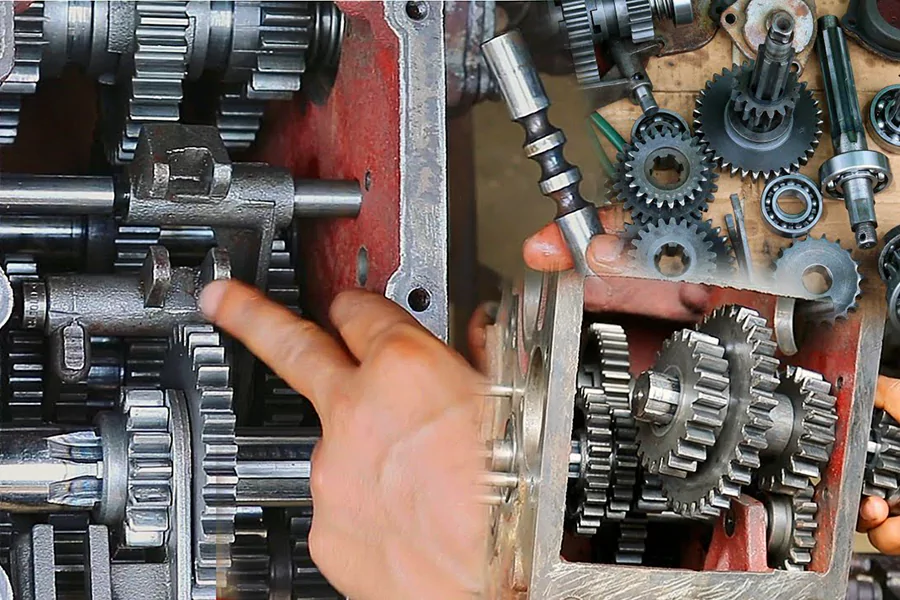

How to Size a Rotary Tiller Gearbox: Torque, Horsepower, and Input Speed Explained

Sizing a rotary tiller gearbox correctly is essential for reliable performance, long life, and operator safety. A proper match balances the tractor’s PTO horsepower, the tiller’s working geometry (width and tine arrangement), soil conditions, and the gearbox’s torque and speed ratings. This guide explains what to check, how to calculate useful numbers, and practical tips for choosing the right rotary tiller gearbox for your application.

Why correct sizing matters

If a gearbox is undersized you’ll see premature wear, overheating, sheared splines, or sudden failures. If it’s oversized you’ll add unnecessary weight and cost. The gearbox transfers the tractor’s PTO energy into the rotor; its torque rating and input-speed compatibility are the technical limits that control whether the whole tiller will operate safely and efficiently.

Key Factors for Sizing a Rotary Tiller Gearbox

1. Tractor PTO Horsepower (PTO HP)

Your tractor’s PTO horsepower is the foundation of gearbox sizing. Rotary tillers draw power directly from the PTO, and manufacturers usually supply recommended PTO HP ranges for each tiller width and model. Always use those ranges as your first filter when selecting a gearbox.

2. Tiller Width

Wider tillers require more power. Common guidance includes ranges such as:

15–25 HP for 36–48 inch tillers

25–40 HP for 48–60 inch tillers

40–65 HP for 60–72 inch tillers

These values vary between manufacturers, so rely on your tiller’s specific recommendation.

3. Soil Conditions and Tine Count

Soil type has a major impact on power demand. Hard-packed clay, rocky soil, or sod needs far more torque than loose, loamy soil. Tine count also matters: a rotor with more tines offers more cutting edges, increasing the load on the gearbox. In some cases, adding additional tines on a 5-foot rotary tiller can push the required horsepower from around 25 HP to more than 30 HP.

4. Gearbox Torque Rating

The gearbox torque rating is one of the most important specifications. It must safely handle the torque your tractor produces at the PTO, including shock loads from stones or abrupt resistance. This torque requirement is different from the tiller’s overall horsepower rating—gearbox torque is the real technical limit.

5. PTO Input Speed (540 / 1000 rpm)

PTO horsepower translates into different torque levels depending on RPM. A 540 rpm PTO produces more torque for the same horsepower than a 1000 rpm PTO. Always check that the gearbox is rated for the PTO speed you will be using.

How to Apply These Factors

Match Tractor to Tiller

Start with your tractor’s PTO horsepower:

15–25 HP → suitable for 36”–48” tillers

25–40 HP → suitable for 48”–60” tillers

40–65 HP → suitable for 60”–72” tillers

These ranges assume normal soil conditions and typical tine counts. Increase the required horsepower if you expect heavy conditions or aggressive tine configurations.

Understand the Gearbox’s Role

The gearbox handles all power transfer between the PTO and the rotor. Not all rotary tillers can match every tractor—the gearbox must be designed for both the torque and PTO speed you will apply. Undersized gearboxes often fail quickly even when the tiller width appears compatible.

Account for Tilling Action

Reverse-rotation tillers, deep-pass tillage, or heavy clay will increase power demand. More tines, more soil contact, and more depth all translate to more torque. Choosing a gearbox with a comfortable safety margin is always wise.

Ensure Proper Driveline Fit

The PTO driveline must be the correct length:

If it’s too long, it can bottom out and damage bearings on both tractor and tiller.

If it’s too short, there may not be enough overlap for safe operation, risking driveline separation.

Always adjust the driveline length according to the manufacturer’s instructions.

How to Calculate Torque from HP and PTO Speed

A useful formula for estimating input torque is:

Torque (lb-ft) = (HP × 5252) / RPM

To convert to metric:

Torque (Nm) = Torque (lb-ft) × 1.35582

Example:

A 30 HP tractor running at 540 rpm produces:

Input torque ≈ (30 × 5252) / 540 ≈ 291.6 lb-ft

In Nm ≈ 291.6 × 1.35582 ≈ 395.5 Nm

If your rotary tiller gearbox has a 2:1 ratio and around 90% efficiency, its output torque would be approximately:

395.5 × 2 × 0.9 ≈ 712 Nm

Your gearbox must exceed this torque rating with a suitable margin.

Quick Selection Checklist

Check the tiller manufacturer’s recommended PTO horsepower.

Calculate tractor torque at PTO speed using the formula above.

Compare torque needs with gearbox torque rating and add a safety margin.

Confirm input spline, rotation direction, mounting pattern, and gear ratio.

Verify PTO driveline length and minimum overlap.

Choose a gearbox suited to soil type and tine configuration.

REQUEST A QUOTE

OR GET MORE

INFORMATION

Leave us a message. We will contact within 12 hours.